Design

From RIBA Stage 0 to RIBA Stage 7, you’ll benefit from collaborative workshops with Merit’s experienced engineers and designers to refine a design that meets your operational needs.

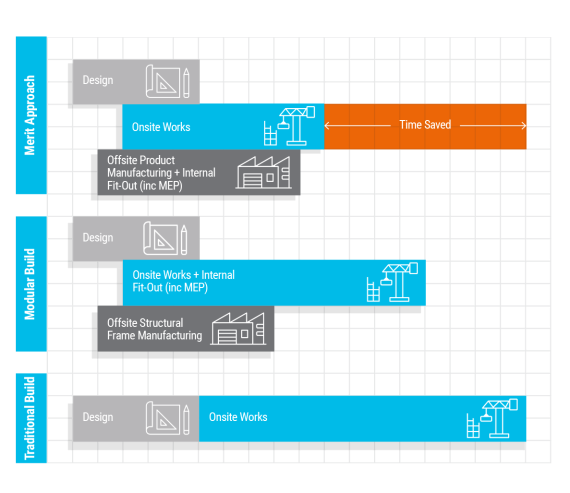

We use a parallel processing approach, so once architecture and 1:200 detailed floor plans are approved, all designs—controls, mechanical, electrical, and structural—proceed simultaneously, eliminating delays and speeding up your project.

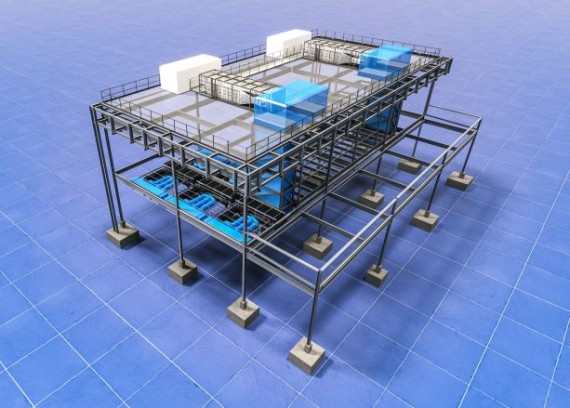

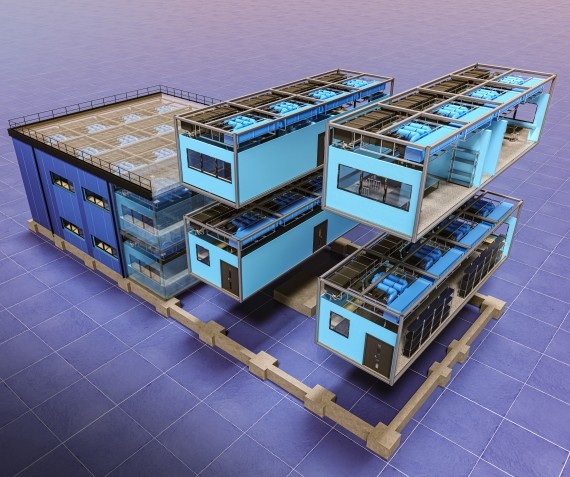

With 4D BIM technology, we convert schematic designs into a 3D model, ensuring manufacturability before production begins.

This advanced modelling allows for personalisation, enabling you to achieve the ideal height, shape, and layout for your build. Additionally, we work closely with an embedded civil and structural design team to integrate specialised expertise when needed.